Out On The Floor...

Continuing our series of exploring all the many aspects, processes, and departments that go into the production of luxury leather, we once again take a trip “Out On The Floor” (previously here and here).

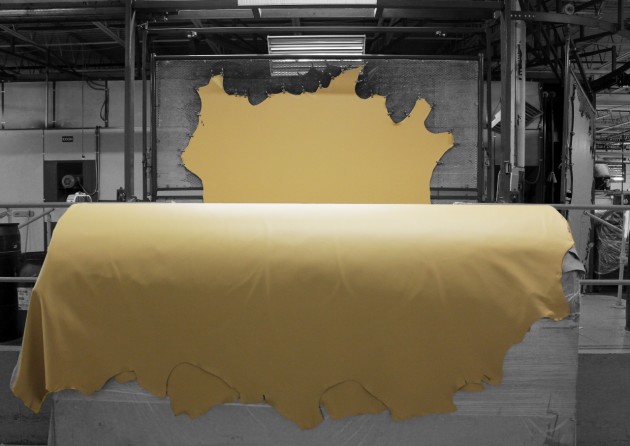

A pivotal moment in the production process.

TOGGLING.

The guys working in the toggle department, work with unparalleled speed and grace.

Reaching to every nook and cranny of a hide, to pull it to its best shape. They work with so many metal toggle hooks, hides, and toggle boards – they can nearly do it in their sleep. But, this certainly is not a sleepy mindless task, this job takes focus and expert understanding of the structure of the hide.

In the toggling department, the craftsmen lightning-quick assess the hide for its optimal shape and size, then get to work – grabbing each edge, each outlier, each neck, shoulder, leg, and bit of the hide. They gently and carefully stretch it in equal distribution – all 4 partners moving in sync to perfectly balance the hide on the board.

The hide is stretched to reduce the visibility of wrinkles, to help smooth the grain of the hide, and to stretch it to its full capacity in order to reduce any shrinkage.

The hide will hang and slowly dry and acclimate to its optimally flattened position, for an average of 6 to 8 hours.

Cycling through the machine, then carefully being removed in its one-of-many steps toward becoming beautiful luxurious leather.