Townsend is a Proud Member of the USGBC

Townsend Leather proudly wears this badge of honor…

We are proud to have become a USGBC Member. Townsend Leather believes strongly in sustainable practices and focusing on the “triple bottom line” – Social, Economic, and Environment.

Townsend Leather recognizes the ever-increasing importance of being socially and environmentally responsible along with creating a business that can continue to support our customers for years to come. Which is one of the many reasons we have joined the United States Green Building Council.

TOWNSEND LEATHER, PROUD USGBC MEMBER

From the USGBC website,

“The U.S. Green Building Council (USGBC) and its community are changing the way buildings and communities are designed, built and operated.

We believe in better buildings; places that complement our environment and enhance our communities. Places that give people better, brighter, healthier spaces to live, work and play.”

Townsend’s products have been used in thousands of buildings and we are proud to know that we have helped them become a bit more green in their creation.

“Your USGBC membership designates you as a leader in sustainability, a driver of green building innovation, and an advancer of smarter, more healthful communities.”

Townsend is committed to sustainability and environmentally positive practices from start to finish.

TOWNSEND LEATHER SUPPLY

All of our hide supply is a byproduct of the meat industry. If the hides were not reclaimed from the meat industry and kept out of the waste stream, they would be sent to an incinerator. So, leather is inherently green, right from the start.

Every part of the hide is used. The hide is a byproduct of the food industry, and as the hide is produced every byproduct of that production is used as well. Byproducts of hide production are used in the pet food and cosmetics industries.

Townsend’s Bulls and Cows are raised in temperate climate in environmentally safe and socially responsible ways – they are free range and allowed to mature naturally.

All of Townsend’s suppliers use the most technologically advanced machinery and processing to ensure they are using the minimum amount of energy to tan the leather. Our leather is sourced from suppliers located primarily in countries in Europe. The hides are already tanned and the tanning process is strictly regulated in the European Union to assure minimal environmental impact. TOWNSEND LEATHER’S GREEN STATEMENT

PRODUCTION PROCESS

Everything in Townsend Leather’s production is highly monitored and anything that leaves the building, through the air or water, is highly regulated and monitored with very strict requirements. Townsend utilizes its own water treatment plant and effluent waters are monitored and pre-treated before they leave our factory to remove any compounds that do not meet state and federal standards, and then receive additional purification in a state-of-the-art wastewater treatment facility engineered to meet the needs of the leather industry, assuring complete environmental compliance. Townsend uses vegetable based re-tanning agents and water-based finishing systems in its entire leather making.

Townsend is the manufacturer of the leather and therefore has the ability to create just what is needed and reduce waste in real time. Townsend is flexible and has the ability to change things in the middle of an order to ensure the least amount of waste.

Recently we have gone through lots of efficiency investments and improvements like brand new high efficiency spray guns. These are a vital piece of machinery in our production and have helped use reduce material use and energy use by as much as 40% annually! We also have new energy and time savings machines like an automatic rolling machine and hide stakers. We have eliminated some steps of productions by finding new and improved ways, which allows us to use less energy, materials, and time therefore reducing chemical consumption and emissions by 30%.

Townsend’s products are made with water based finishes, free of dangerous chromes, are post-consumer recyclable and are low VOC. Townsend is always keeping on top of the latest in industry trends and information we are the first to try new methods and explore more efficient ways. GOING GREEN TOWNSEND LEATHER BULLETIN

TOWNSEND CULTURE

Townsend has a culture of “going green” with our volunteer “Green Team” and many efforts throughout the company. We are constantly looking for ways to improve and reduce waste. We recycle everything we can including hundreds of thousands of pounds of cardboard, paper, and plastic. As well as leather scraps. Leather scraps can be reused and made into small leather goods like keychains and wallets. Therefore over the past few years Townsend has drastically reduced its waste output.

And by focusing on the best providers, instilling a culture of no-waste, and utilizing low energy machinery and equipment we have also reduced our energy consumption.

Townsend Leather enjoys its own Adirondack-adjacent scenic park and pond and has a small physical footprint of buildings. We participate in annual Earth Day events and cleanup activities, we reuse everything we can and we “strive to make a positive environmental impact.” TOWNSEND LEATHER CLEAN-UP EVENTS

OTHER WAYS TOWNSEND IS SUSTAINABLE

Townsend’s leather is a durable, long-lasting product that does not require replacement or re-processing in order to retain its beauty and serviceability. Unlike fabrics and textiles, leather is easily repaired. Often it can be restored to its original condition when worn or damaged.

Leather is mankind’s oldest textile and is naturally durable. Leather can handle wear and tear that would easily destroy other materials. It is estimated that leather lasts an average of 4 times longer than fabric coverings; the endurance of leather is unmatched. Many leathers will develop a beautiful patina over time, making leather-upholstered pieces “heirlooms” that are cherished and passed down from generation to generation. LEATHER IS ENVIRONMENTAL

Townsend Leather and its sister company, The Leather Institute, are dedicated to providing leather care products and maintenance solutions that preserve the beauty and prolong the life of fine leather seating. The Leather Institute is the premier leather care and restoration training facility in the world, offering training courses in leather care, maintenance and restoration. They use a carefully formulated special line of care and cleaning products that are compatible with today’s water-based leather finishes and will not damage the leather surface. LEATHER IS EASY TO REPAIR

TOWNSEND LEATHER’S CUTTING PROGRAM

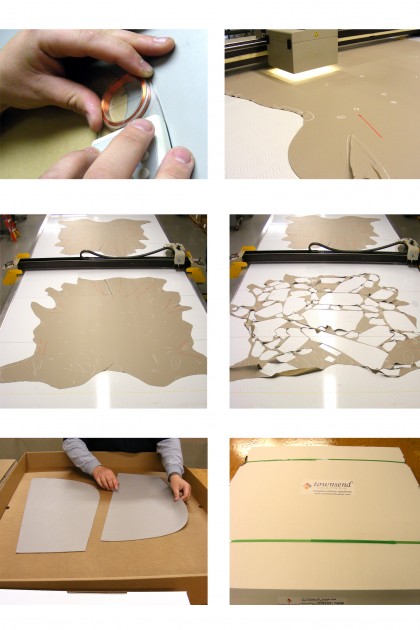

Townsend’s Cutting Program is a waste-slashing program. TOWNSEND LEATHER CUTTING PROGRAM

It is designed to reduce waste in a variety of ways. By utilizing the most technologically advanced cutting system and nesting software you can reduce the amount of hide material needed to fulfill your project. And by using less leather the order weighs less, which means lost cost and energy for shipping. And the small amount of scrap leather that is leftover from the cutting process can be reused by Townsend, making the Cutting Program and fully green process.

By utilizing the waste by-product created by another industry as a raw material, by using the latest technology to exceed all federal, state and local standards for environmental protection, by providing after-marketing support solutions for maintenance and restoration, and by manufacturing a durable, long-lasting product of high quality, Townsend Leather continues to demonstrate its commitment to improving and preserving our planet.

USGBC’s mission: which we proudly adhere to as well…

“To transform the way buildings and communities are designed, built and operated, enabling an environmentally and socially responsible, healthy, and prosperous environment that improves the quality of life.”